How Often Should Line Marking Be Redone? A Data-Driven Maintenance Guide

Why Line Marking Maintenance Isn’t Optional

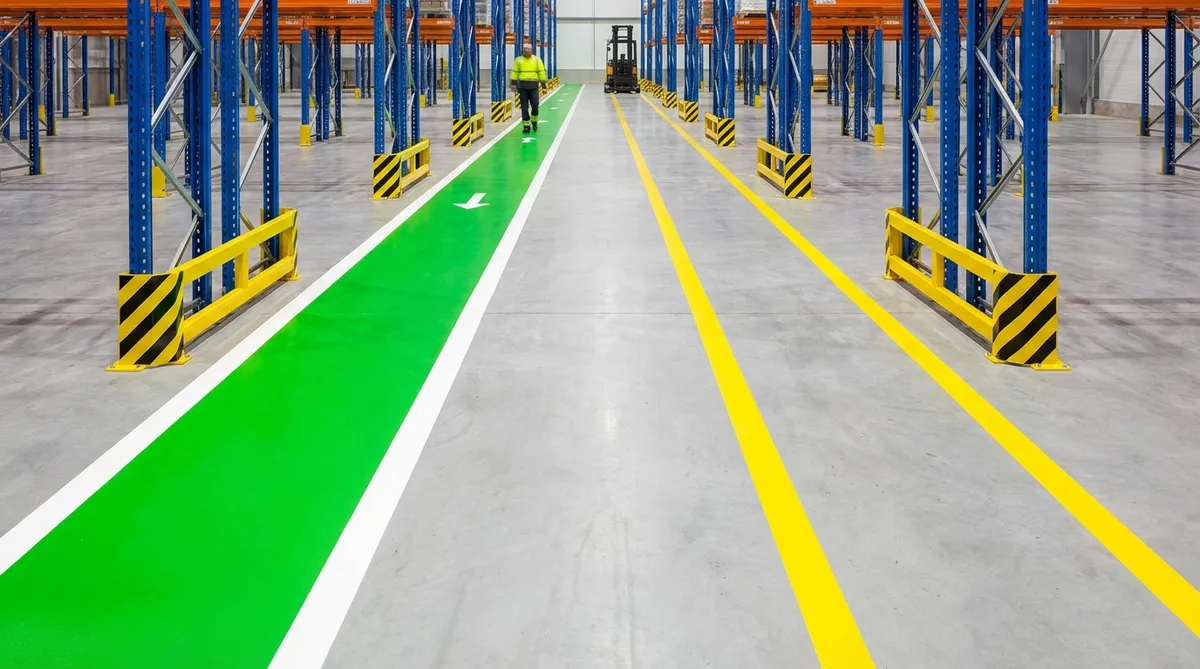

Line marking fades slowly—so most facilities don’t realise how unsafe or inefficient their space has become until it’s already a problem. Forklift paths blur, walkways lose visibility, and car parks develop “ghost lines” that confuse drivers. Australia’s harsh climate and heavy traffic loads accelerate this wear, meaning refresh cycles need to be planned, not reactive. A structured maintenance schedule protects safety, compliance and operational flow.

The Problem: Why Markings Wear Faster Than You Think

Several forces combine to degrade line marking far more quickly than many managers expect:

High UV exposure and temperature extremes:

Australian sun breaks down pigments and binders rapidly, especially in open-air car parks. Even premium coatings chalk and fade under UV load.Forklift traffic creates abrasive wear:

Forklifts apply lateral pressure during turns, dragging tyres across the surface. This shears paint film much faster than passenger vehicles, particularly in warehouses with tight manoeuvring.Moisture, dust and unsealed surfaces:

Concrete that isn’t fully sealed allows moisture to push up from below, weakening adhesion. Dust and fine aggregate act like sandpaper under tyres.Wrong paint selection for the substrate:

Using water-based paints on high-traffic warehouse floors, or solvent paint on damp surfaces, results in premature peeling and patching.Operational changes that invalidate old markings:

New racking layouts, revised forklift paths, or changed pedestrian routes often leave outdated lines that confuse operators.

The Solution: A Data-Driven Refresh Schedule

Rather than waiting for a Worksafe inspection or safety incident, facilities should build a predictable refresh cycle based on five measurable variables: traffic load, surface type, environment, coating type and operational risk.

A practical Australian guideline looks like this:

1. High-Traffic Warehouses (Forklifts, Reach Trucks, Order Pickers)

Refresh every 6–12 months, depending on the density of movement and turning stress.

Forklift-intensive sites with tight aisles and constant reversing will sit toward the lower end. Epoxy or MMA coatings push the cycle longer than water-based paint.

2. Car Parks (Retail, Commercial, Strata)

Refresh every 12–24 months, depending on UV exposure and weather.

Open-air car parks degrade fastest. Underground or shaded areas often last 2+ years with premium paint.

3. Loading Docks & Heavy-Vehicle Zones

Refresh every 6–9 months.

Heavy vehicles crush aggregate into the coating, especially when surfaces are older or poorly sealed.

4. Pedestrian Walkways & Safety Zones

Refresh every 12 months, or sooner if visibility drops below 80%.

Pedestrian boundaries are high-risk, so clarity matters more than lifespan.

5. Thermoplastic & MMA Markings

Service life of 3–5 years in moderate conditions.

These are premium materials suited for sites wanting longer cycles and less downtime.

Why Professional Application Matters

A refresh cycle only works if the markings are applied properly in the first place. Professional contractors extend lifespan through:

Correct coating selection:

Matching paint type to traffic load—epoxy or MMA for forklifts, solvent for outdoor car parks, water-based for light-use interiors.Proper surface preparation:

Grinding or shot-blasting prevents early peeling. Most premature failures are prep failures, not paint failures.Right film thickness and application method:

Airless spray, thermoplastic extrusion or MMA trowel methods deliver sharper, more durable lines than cheap roller jobs.Environmental timing:

Working during low dew point hours, avoiding heat gradients and using fast-cure options to keep operations running.Scheduled maintenance programs:

Facilities with recurring needs benefit from predictable site visits, ensuring markings never drop below safe visibility.

These elements mean the difference between a line that lasts three months and one that lasts three years.

Conclusion

Faded line marking isn’t just a cosmetic issue—it directly impacts safety, traffic flow and compliance. A data-driven refresh schedule ensures your markings remain clear, durable and operationally effective, reducing risk and avoiding costly downtime. When line marking is treated as planned maintenance rather than an afterthought, facilities run smoother, safer and with fewer surprises.