Warehouse Line Marking Standards: What Australian Facilities Get Wrong

The Hidden Compliance Risks in Warehouse Line Marking

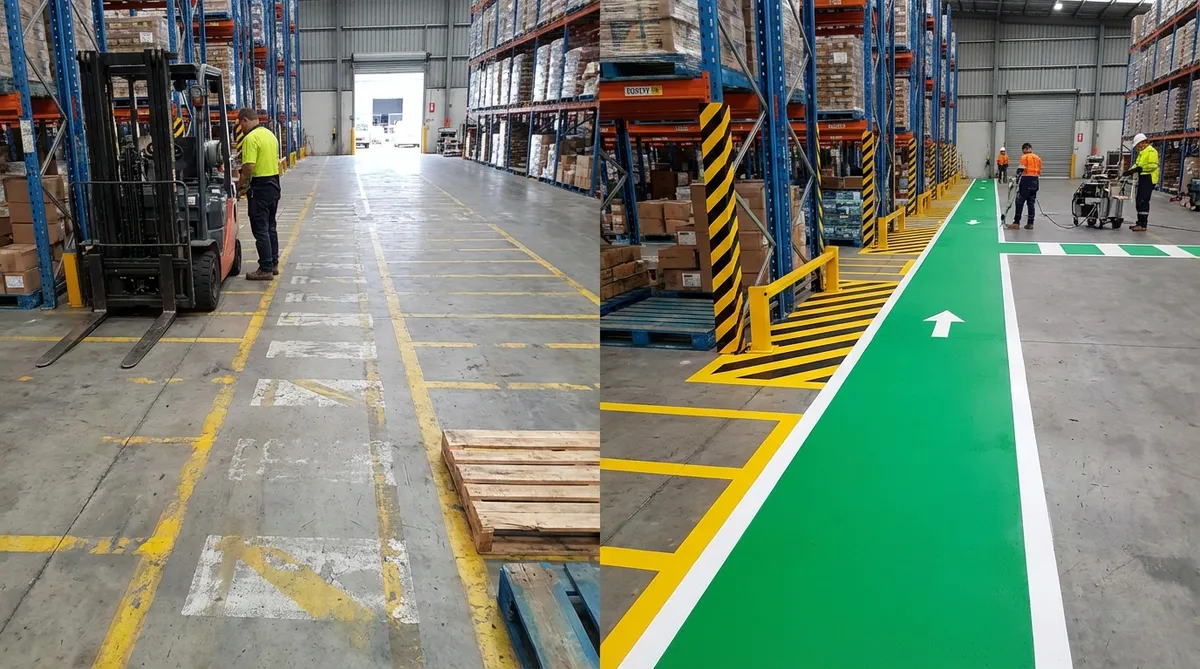

Most warehouses think their line marking is "good enough" until they miss an audit, have a near-miss with a forklift, or face a Worksafe inspection. The reality is simple: poorly planned or outdated markings create safety risks, slow down operations and expose the business to avoidable compliance issues. Australian standards aren't complicated—but they're routinely misunderstood or ignored.

The Problem: What Facilities Commonly Get Wrong

Despite having safety systems in place, many warehouses still fall into the same traps:

Walkways that don't follow AS/NZS conventions: Pedestrian aisles are often too narrow, the wrong colour, or inconsistent with the safety palette. This creates ambiguity—forklift drivers assume space is shared when it isn't.

Forklift exclusion zones that aren't clearly defined: Many sites rely on old, faded markings or improvised hatched areas. A forklift zone must visually "read" as restricted instantly, or it will be ignored under pressure.

Racking areas that fail standard spacing and hazard marking guidelines: Racking legs, end-of-aisle zones and picking aisles often miss mandatory hazard edging (diagonal yellow/black), causing repeated damage and operational downtime.

Inconsistent colour usage across the site: Using yellow for everything—walkways, hazards, storage areas—removes meaning from the markings. Colour equals instruction, and inconsistent colour = inconsistent behaviour.

Old markings left visible after layout changes: Ghost lines are one of the biggest causes of workflow errors. Drivers default to the old route, increasing collision risk and failing audits.

The Solution: Clear, Consistent, Standard-Aligned Marking

Correcting warehouse line marking is rarely about "more paint." It's about making the space readable at a glance.

A high-performing warehouse marking system includes:

Clearly defined pedestrian walkways: Typically in solid green pathways with white edging or compliant alternatives. Minimum widths matter, especially in high-traffic zones.

Dedicated forklift routes: Strong, high-contrast lines that visually isolate machine paths. Incorporate hatched hazard zones near intersections and doorways.

Consistent hazard identification: Yellow/black diagonal hatching for impact areas, racking corners, and "no-go" spaces. This is a universal visual language—your operators already understand it.

Logical flow design: Arrows, symbols, numbering and zoning that reinforce how the warehouse actually operates. A layout that mirrors operational flow improves throughput instantly.

Removing old lines before adding new ones: Shot blasting, grinding, or chemical removal prevents confusion and gives new coatings proper adhesion.

Why Professional Application Matters

DIY marking fails for one reason: warehouses aren't static environments. The coatings, timings, and prep need to be matched to the realities of forklifts, dust, cold rooms, moisture, and heavy traffic.

A professional team delivers:

- Correct paint selection: (water-based, solvent, 2-pack epoxy, or thermoplastic) based on surface and traffic load.

- Surface prep that actually lasts: Grinding or shot blasting where required—not just painting over dust.

- Fast cure times to avoid downtime: We plan around shift changes or weekends so the site stays operational.

- Access to industrial-grade equipment: Airless sprayers, precision line machines, and stencils designed for compliance.

- Layout design input: Experienced operators know how forklift behaviour, picking patterns and pedestrian flow influence safety—something most contractors miss.

This combination is what separates proper industrial line marking from tradie-grade paint jobs that fail in weeks.

Conclusion

Warehouse safety isn't just PPE and training—it's the markings that tell every person and every machine where they're supposed to be. Clear, compliant, professionally applied line marking cuts collision risk, passes audits and keeps operations moving without interruption. If your markings are inconsistent, faded or unclear, fixing them is one of the simplest high-impact upgrades you can make.